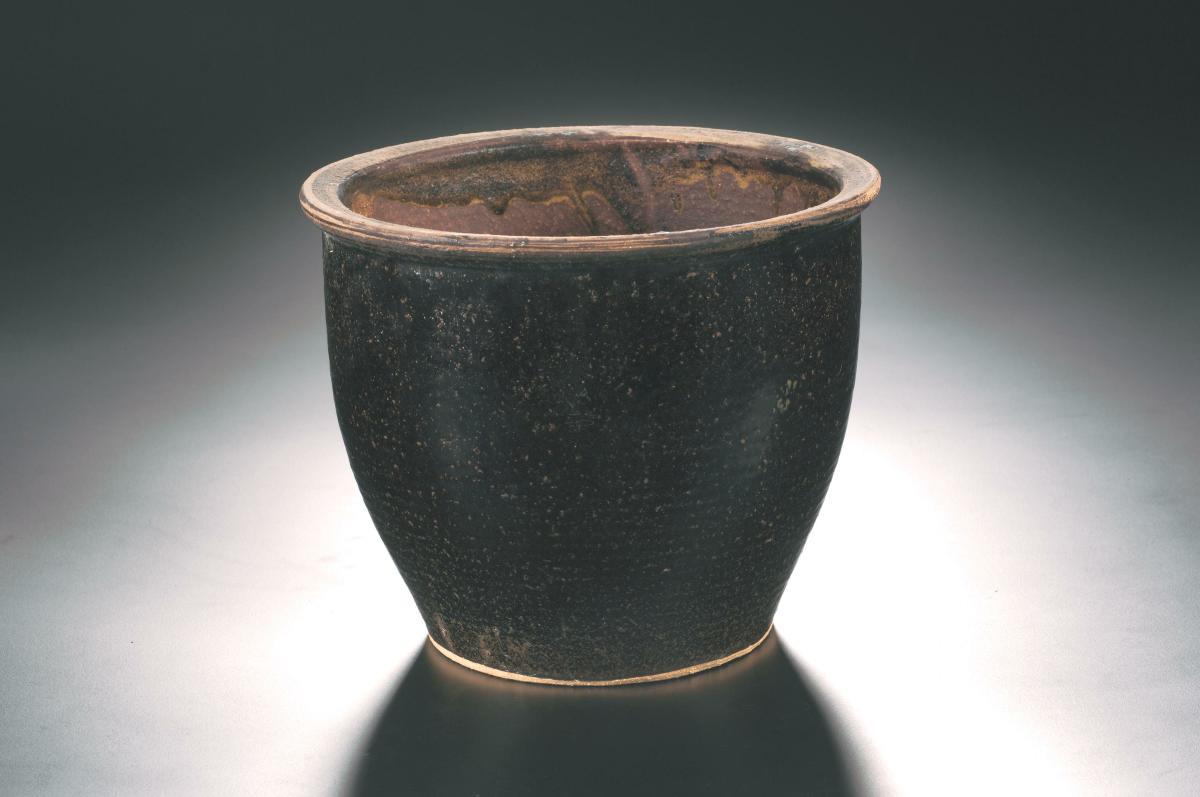

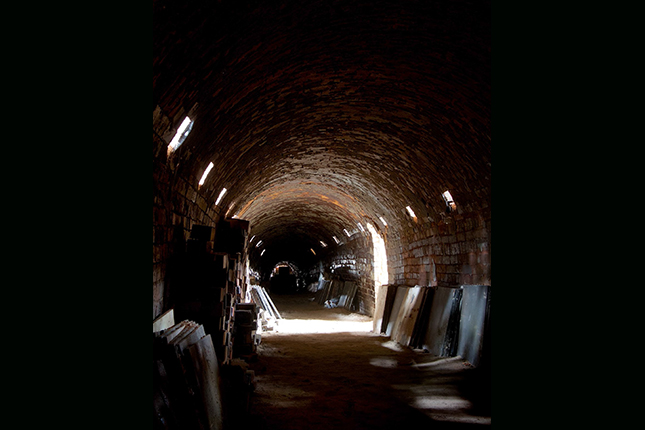

This large, beige-glazed stoneware pot has a wash of brown slip (liquid clay) inside. The interior, mouthrim, and the base remain unglazed, revealing reddish-brown body. It is one of the modern designs fired at the Sam Mui Kuang dragon kiln to hold plants. Sam Mui Kuang dragon kiln was set up in Jalan Hwi Yoh in Singapore in the 1940's by Mr.Chua Eng Cheow, a potter from Fujian province, China. A wide range of utility wares were made for the local market and for export, using carefully refined local clay and glazes. Traditional and modern techniques were used including electrical and kick wheels, hand-building and moulds. About 60% of the wares were moulded. One of the most unique features of the kiln was the natural glazes made from local clay and pigments. The potters mined and cleaned the clay themselves and made all the pots by hand.Dragon kilns were developed in southern China over 2000 years ago during the Warring States period (481-256 BCE). The Kuang kiln was 42m long and took over 36 hours to fire. Using around six tons of firewood for fuel, a temperature of 1280 degrees celsius could be reached - the right temperature for firing stonewares. Thousands of pots could be fired each time. One of the last surviving dragon kilns in the region, Sam Mui Kuang was closed down during the 1980's to make way for urban redevelopment. Today Mr. Chua's sons continue the family tradition through their work as studio potters, who create pots as works of art. By the 1980s, mass produced flower pots and other utility wares were already being produced using electric kilns by competitors.